Products

製品情報

PLUSTER ボトムフィード

オフラインブランクス検査装置

パッケージ

枚葉オフセット印刷

クリアカートンや変形品検査可能!

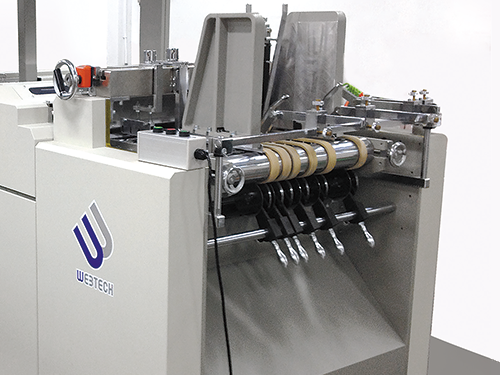

ボトムフィードタイプのオフライン ブランクス検査装置

ボトムフィードタイプのオフライン ブランクス検査装置

特徴

ボトムフィードタイプ

PLUSTERのフィーダーはサックマシーンと類似した機構をもつため、ブランクスを扱うお客様であれば簡単にフィード調整が可能です。

高分解能カメラをブランクス特化で設置

高性能4096bitカメラをブランクスのサイズに特化させて使用しているため、画素分解能0.14mm×0.14mmの高精度。

細かい欠陥も見逃さず撮像可能です。

要望に合わせて搬送機改造可能

お客様の様々な要望に合わせて特殊仕様の搬送機設計も対応可能です。

是非、ご要望ください。

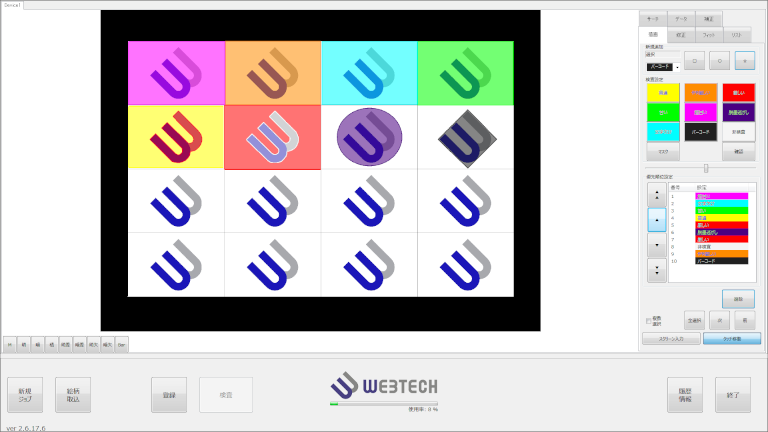

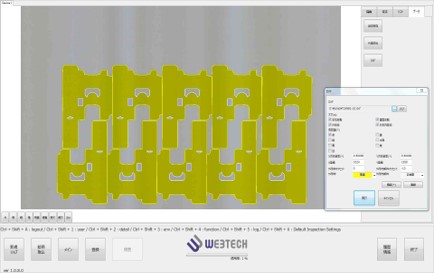

検査ソフトは弊社製SENSAIを実装

印刷品質検査ソフトとして長年の実績を持つSENSAIを実装。

オフライン向けの機能を搭載し、確実かつ簡単な検査を行えます。

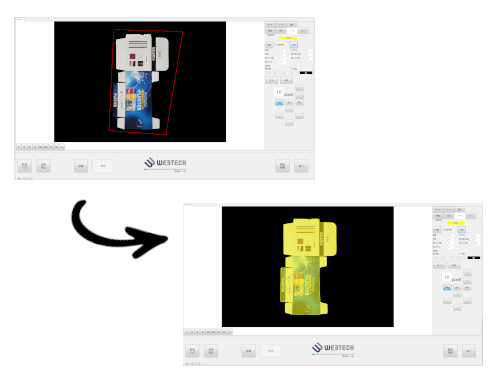

煩雑なエリア設定を簡略化するフィット機能

多様な形状を持つため、エリア描画が煩雑なブランクス検査ですが、SENSAIのオプション機能である「フィット機能」を用いれば外形を抽出し、自動的にエリア設定が可能になります。

外側を大まかに囲ってワークと背景の境界線を見つける「外側モード」

ワークの特徴から類似エリアを判別してエリアを引く「内側モード」

※画像は外側モード

DXFデータ読み込みによるエリア設定

さらにエリア設定を簡略化するために、DXF読み込みオプションもございます。

打ち抜き用のDXFデータをそのまま検査エリアの型として読み込めます。

検出可能欠陥例

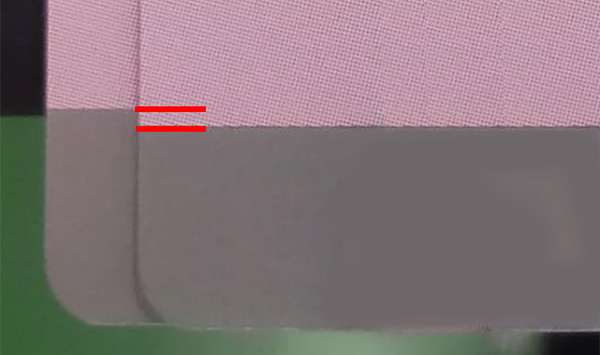

抜きズレ

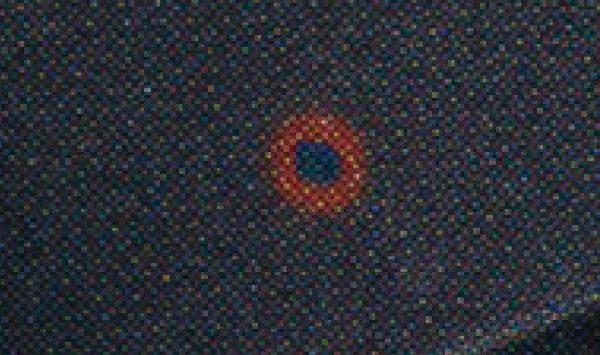

ヒッキー

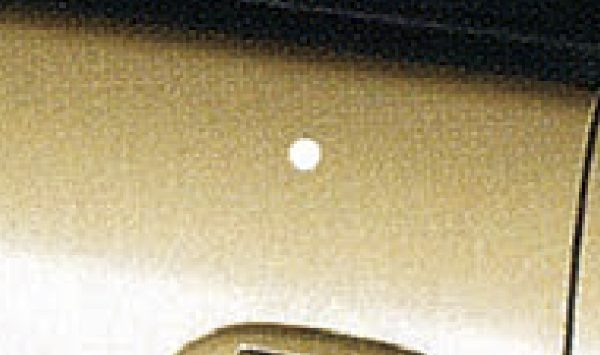

ピンホール

地汚れ

水だれ

ダブり

色ムラ

PLUSTER_Bottom_feed

ブランクス用オフライン品質検査装置