Products

製品情報

SENSAI-CP type.c

コルゲーター用品質検査装置

段ボール生産

合紙工程向けに専用設計されたハードウェアとダンボール向けにカスタマイズされた検査ソフト!

独自のパレタイザシステムを備え、検査のみならず、不良抜き取りの確実性や効率をアップ!

独自のパレタイザシステムを備え、検査のみならず、不良抜き取りの確実性や効率をアップ!

コルゲーター専用に開発されたインライン検査装置。

検査は合紙工程に専用にチューンアップされたソフトウェア・ハードウェアを搭載。

大量に生産される過程で負担が大きい不良抜き取りも効率化可能。

見つけるだけで終わる検査装置ではありません。

検査は合紙工程に専用にチューンアップされたソフトウェア・ハードウェアを搭載。

大量に生産される過程で負担が大きい不良抜き取りも効率化可能。

見つけるだけで終わる検査装置ではありません。

特徴

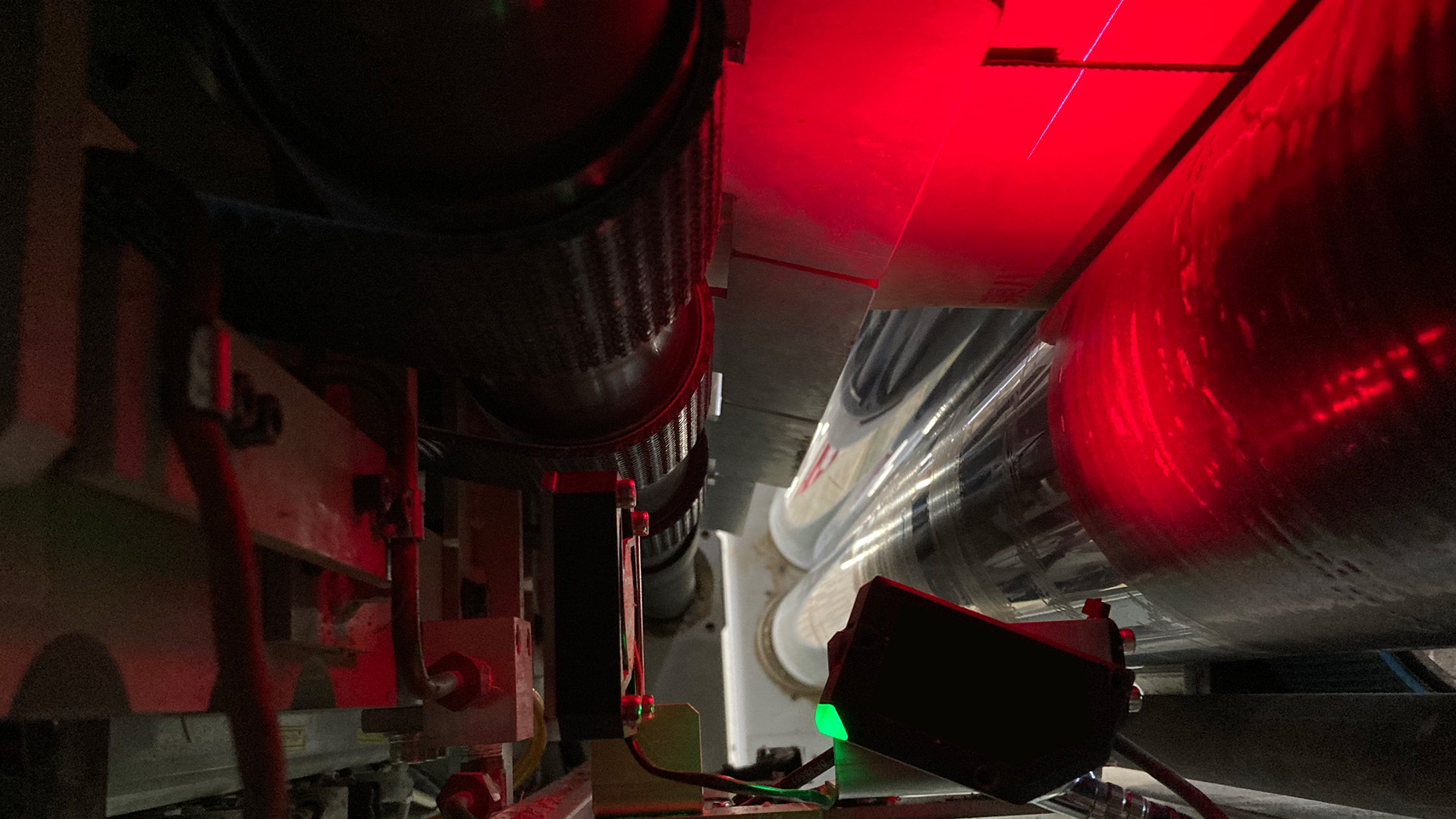

高性能カメラを両面で使用!不良を確実に発見!

409bitカメラを片面に2台ずつ搭載。

ワーク幅が大きいコルゲーターでも、検査に必要とされる分解能を確保。

スリッタスコアラー後に設置可能!

スリッタスコアラー後に設置可能なため、より最終工程に近い位置で検査することで検査機通過後の不良発生・流出を防ぎます。

スリッタスコアラ―周辺で発生する油だれ等を検出可能です。

独自のパレタイザシステムで抜き取りを支援

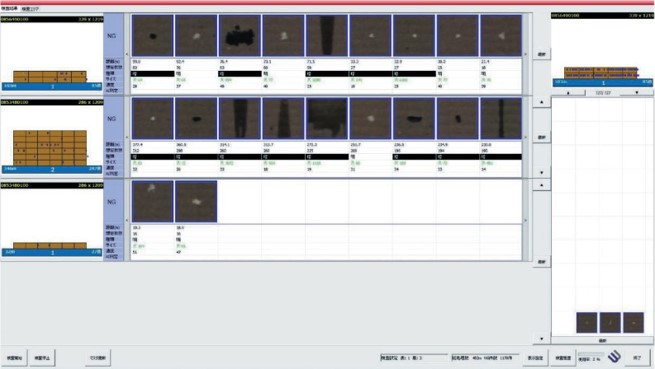

生産完了後、パイル積みされたワークの中から不良紙を抜き取る際に、どのパレットのどの位置に入っているかがわからないと抜き取れません。

弊社のパレタイザシステムは生産と連動し、不良紙の位置を示します。

また、手動でスタッキング替えを行った場合でも追尾し、不良品位置を見失いません。

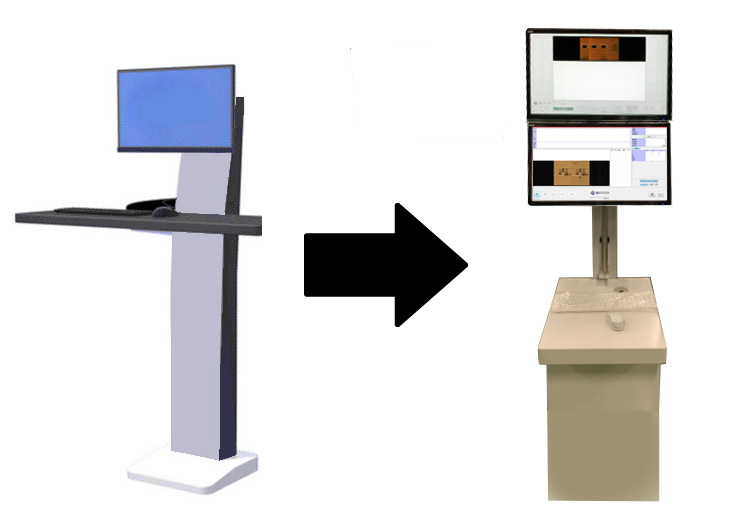

生産機との連動機能

JOB名やワークサイズ、紙種、色数、生産開始等を生産機側から情報を受けとることにより全自動で検査設定を行い、検査を介します。

生産開始時の検査機調整時間を省き、未検査で流れていく製品を減らすとともに、ヒューマンエラーも回避します。